|

How Did Drywall Tools Get in my Woodshop?I think it was a magazine article where I first read about a guy who used drywall screws on a wood project. The article intrigued me enough that next time I was at Home Depot I decided to wander from my more familiar territory (the dimensional lumber aisles) and check out the drywall department. To my surprise I found a few different tools that, oddly enough, were perfect solutions to a host of different problems I was having in my shop. Drywall ScrewsI usually keep this secret to myself, but I prefer drywall screws over wood screws for most of my projects. Why? For starters, drywall screws are thinner, which makes them easier to drive and less likely to split soft wood. I also like the coarse thread, which helps prevent stripped pilot holes.

Keep in mind that I'm talking about building projects with softwood—like pine and poplar. With hardwoods like oak and maple, conventional woodscrews definitely have the advantage. A drywall screw is relatively weak, and can easily snap trying to bring two pieces of dense hardwood together. Also note that the threads of a drywall screw extend along its entire length. With some hardwoods, this can cause bridging—where a screw forces apart the boards you are trying to join. |

Drywall Screws

Drywall Sander

Drywall Sander w/ vacuum

Drywall Square

|

Square Head vs Phillips Head - Most of the drywall screws you’ll see on the shelf take a square head driver. I’m not a big fan of the square head system, but don’t tell anyone. A lot of people (and I mean a lot!) swear by these fasteners and would never use anything else. If you don’t mind using square head drivers, you’re in good shape. Otherwise, you might have to do some digging around on the shelf to find the drywall screws with a Phillips head (don’t give up, they’re in there somewhere).

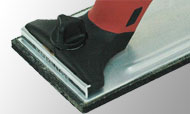

Drywall Sanding TrowelThis was a no-brainer for me. The big, comfortable handle on a drywall sanding trowel makes sanding wood projects a whole lot easier than using a conventional “wood” sanding block. I should mention that fitting the trowel with typical sandpaper (made for wood sanding) will leave a little waste. For example, a standard 9x11 sheet will give you two full pieces for the trowel, leaving a couple inches of unused paper along one side. (No problem for me -- I use these pieces for detail work!).

Another thing I love about drywall sanders is the optional vacuum attachment you can get with some models. I’m not sure I’ve ever seen cool accessories like this designed for wood sanding blocks, at least not at these prices. Sure, I suppose I could always attach my powered palm sander to my powered shop vac – but I don’t even want to think about the decibel levels that would blast from that combination ( I quit using powered hand sanders a long time ago because I couldn’t escape the horrible noise – even with ear plugs).

Drywall SquareMost of the wood projects I build include a piece of plywood at least somewhere in the design. That means I spend a lot of time cutting down large plywood panels into smaller sections. I’ve tried plenty of methods for marking a cut line across the 48” width of a panel (and I keep looking for new ones!), but more often than not I bring out my trusted drywall square to get the job done. I think what I like best about my Johnson square is its weight. It’s made of super-light aluminum, and weighs in at a mere 2 -1/2 pounds. It’s a tough tool, though. The manufacturer guarantees the head will stay square for the life of the product.

In addition to marking cut lines, I also the drywall square to align project pieces on an assembly table. Once my project pieces are lined up snug and tight to the square, I clamp everything down, drill the pilot holes, and drive the fasteners. This method guarantees a perfectly-square assembly (or as close to perfect as anything needs to be!).

|